OPTIMIZE YOUR STORAGE SPACE

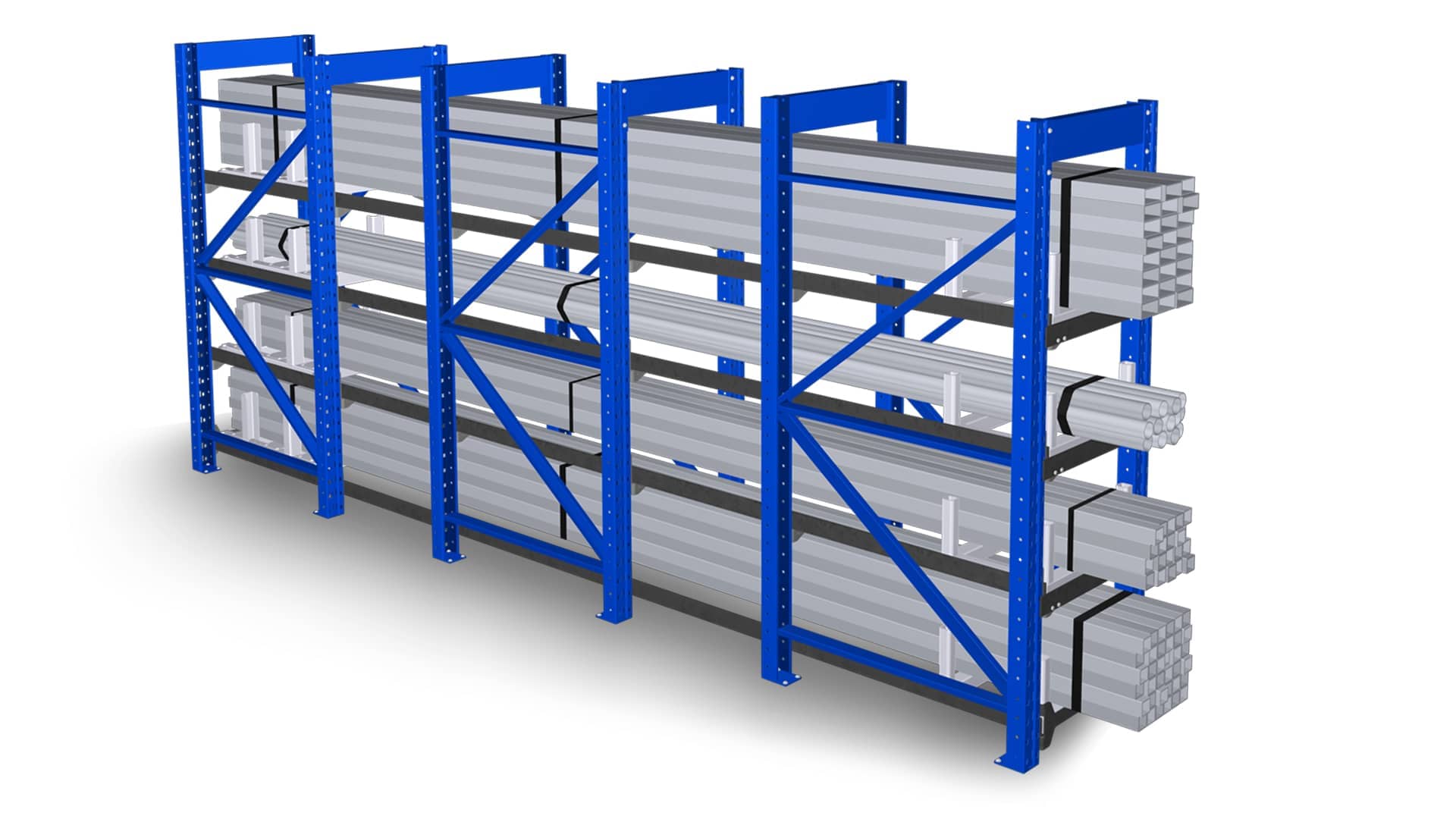

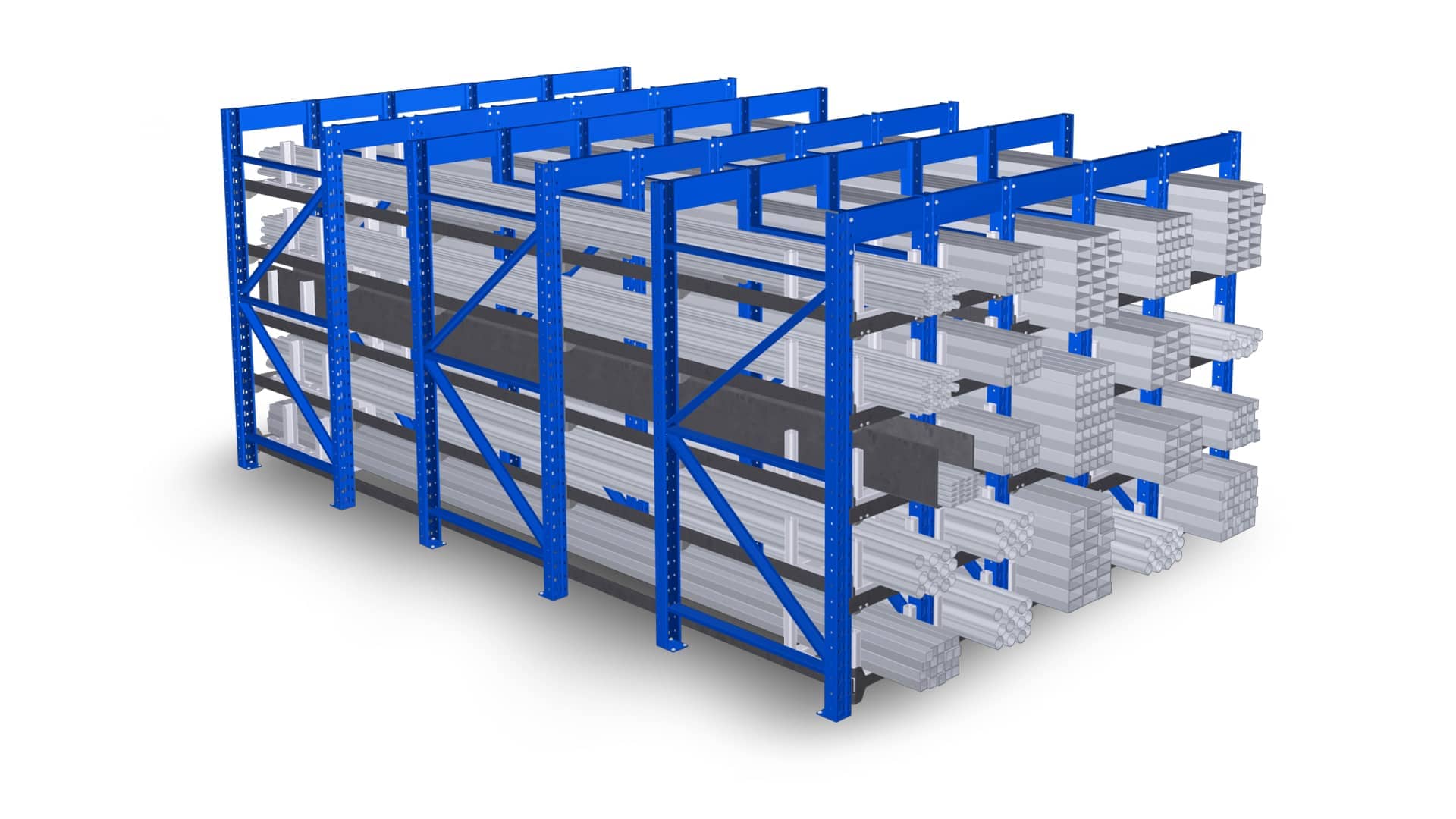

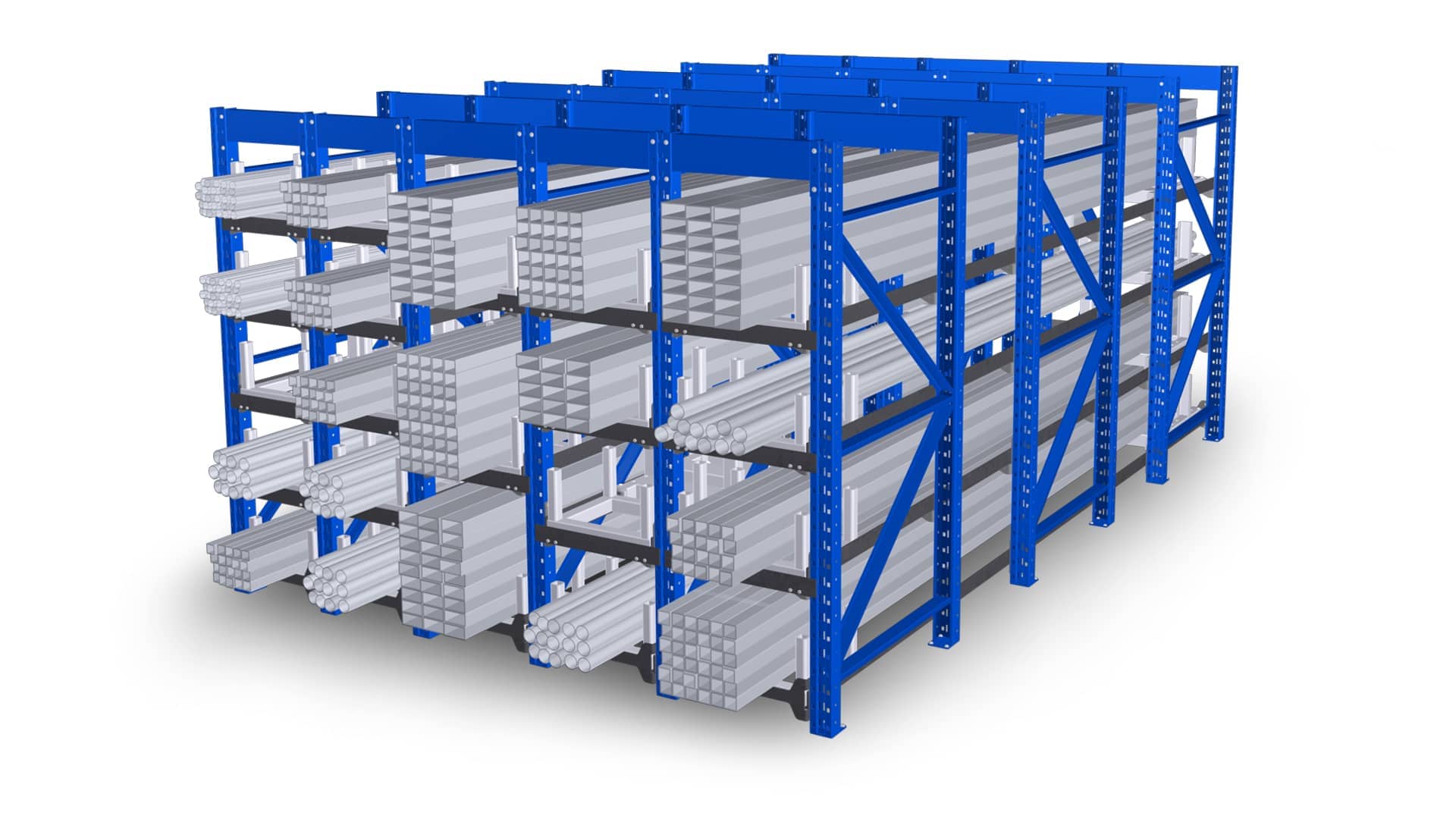

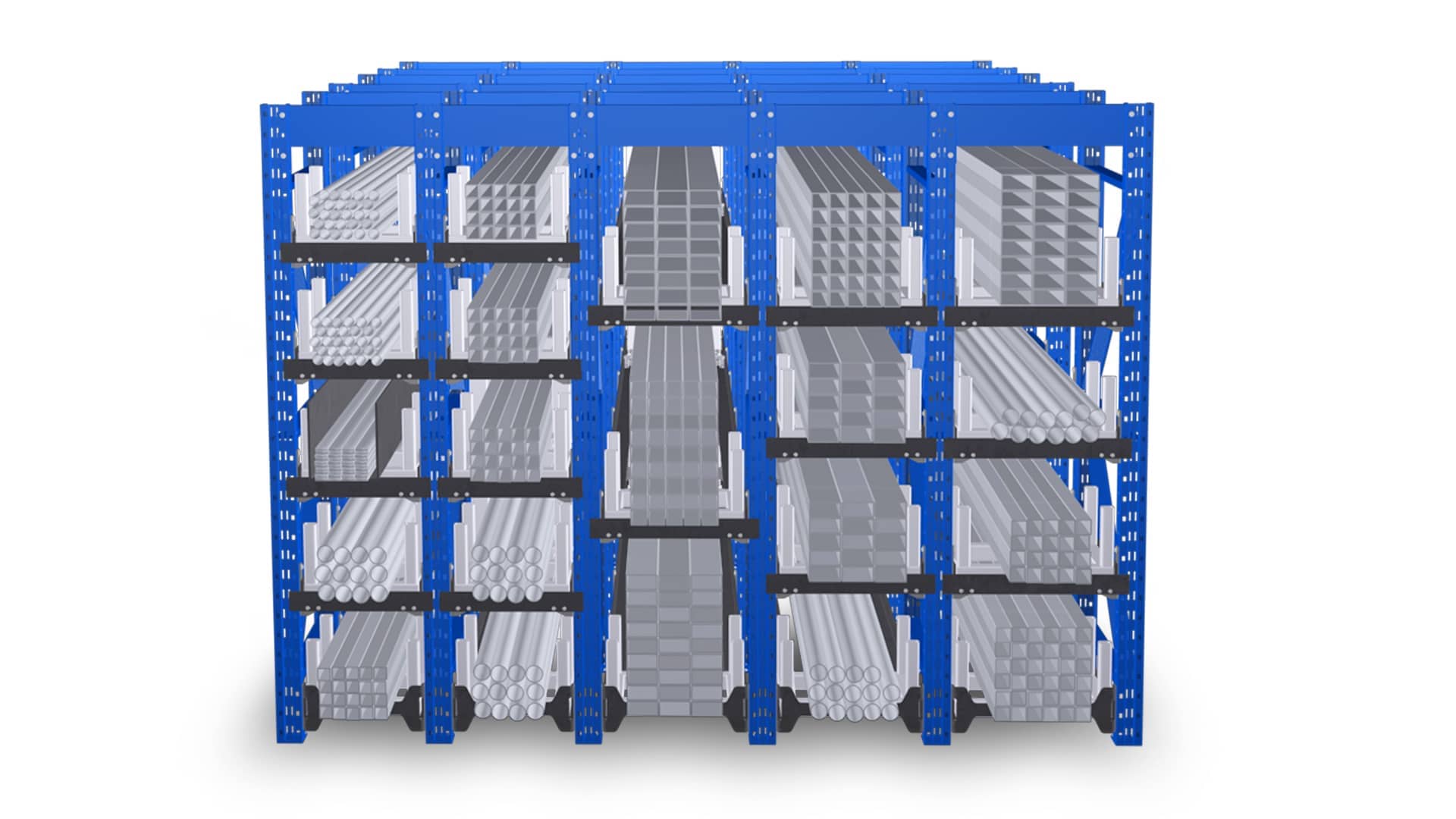

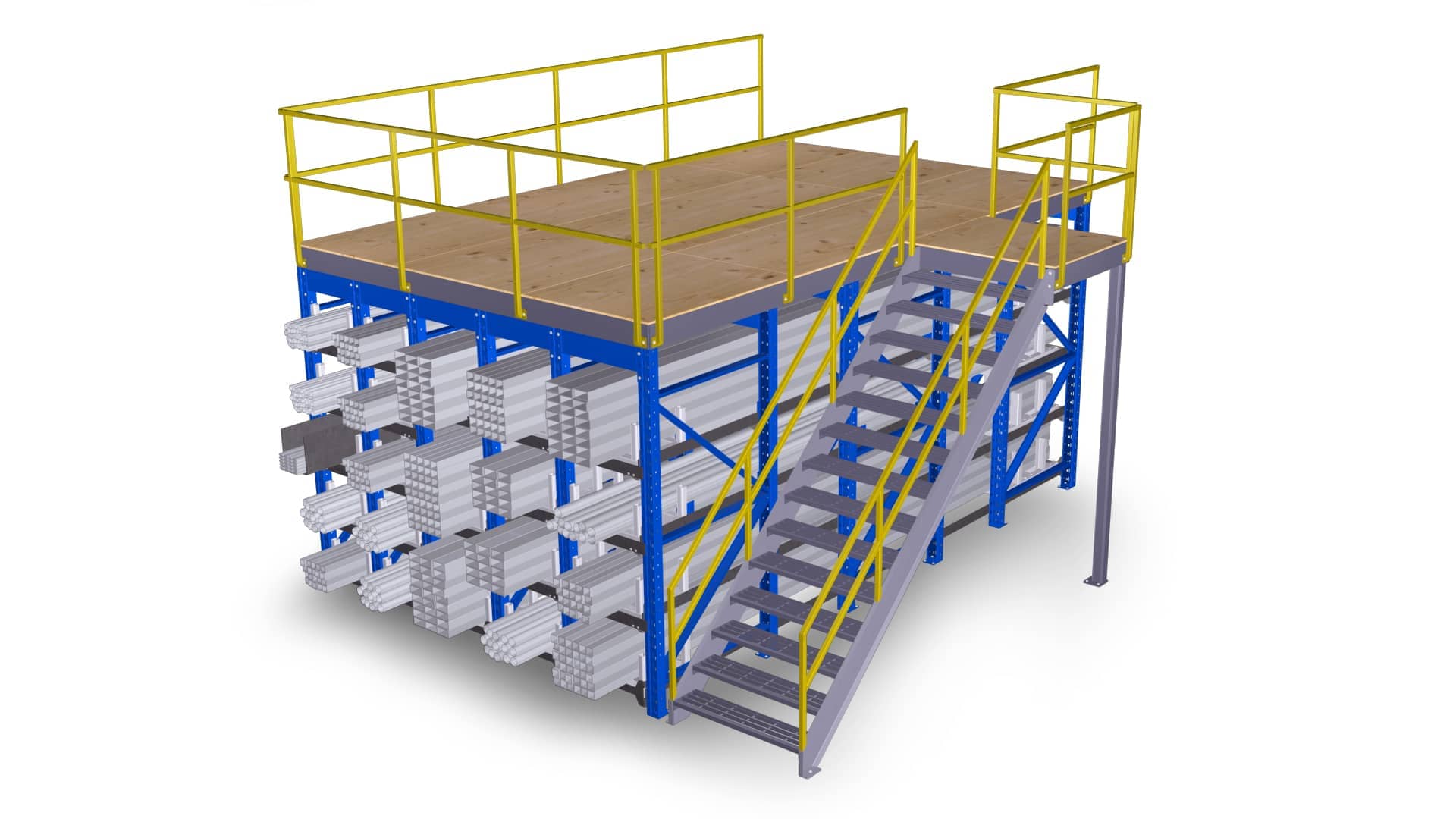

The honeycomb rack gives you instant access and offers you the perfect solution for the storage of tubes, bars, flat bars and/or angles.

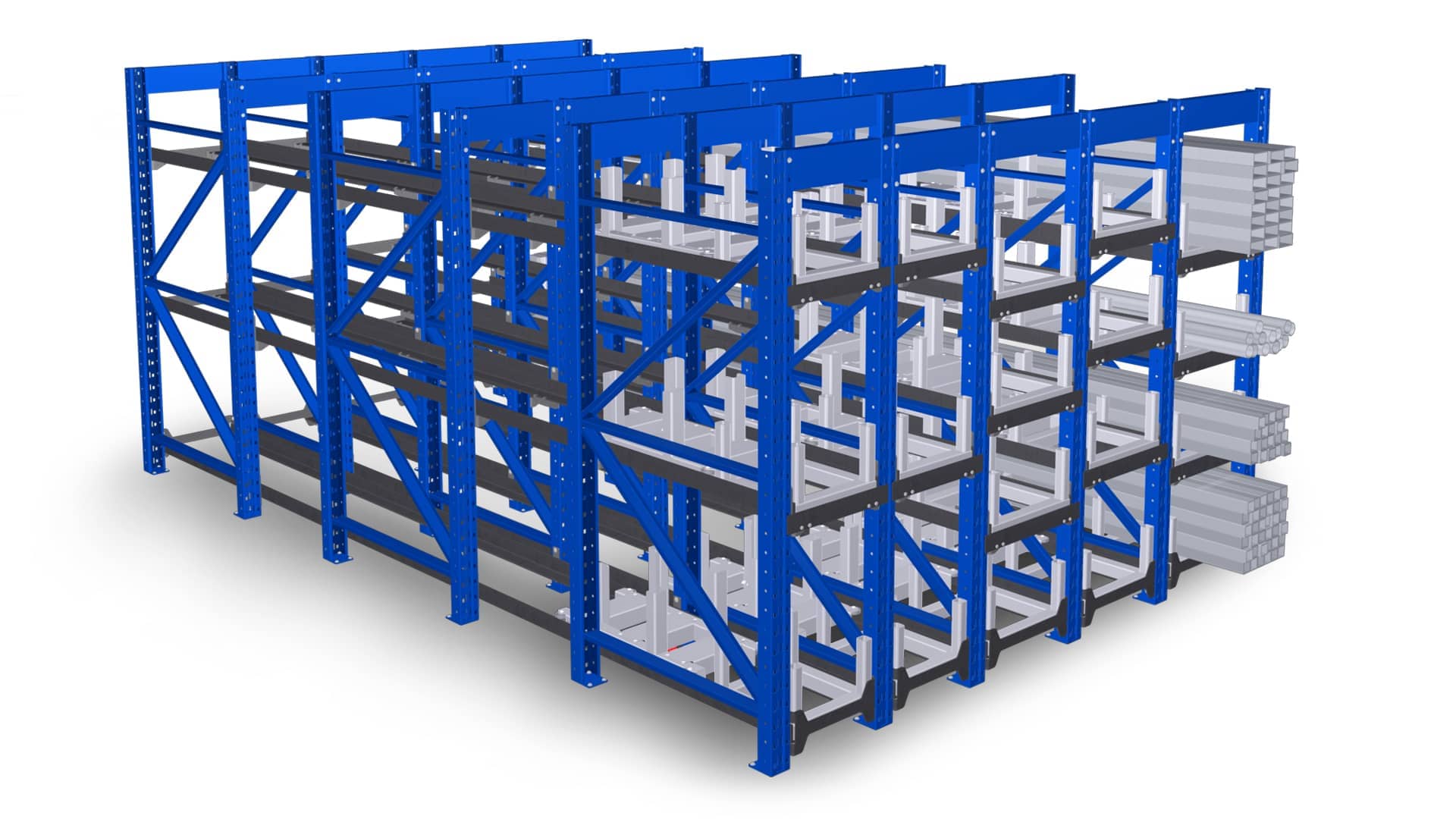

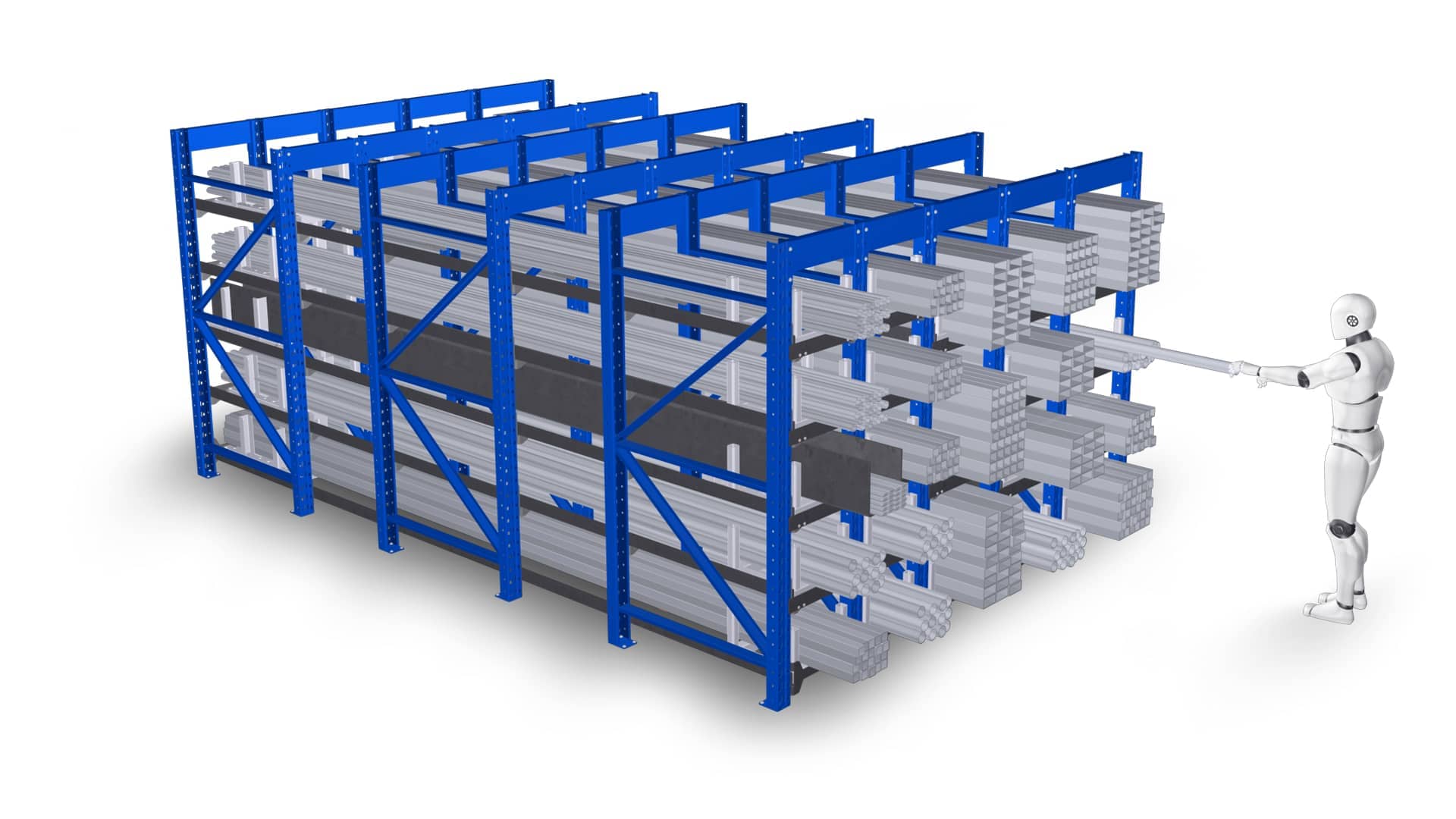

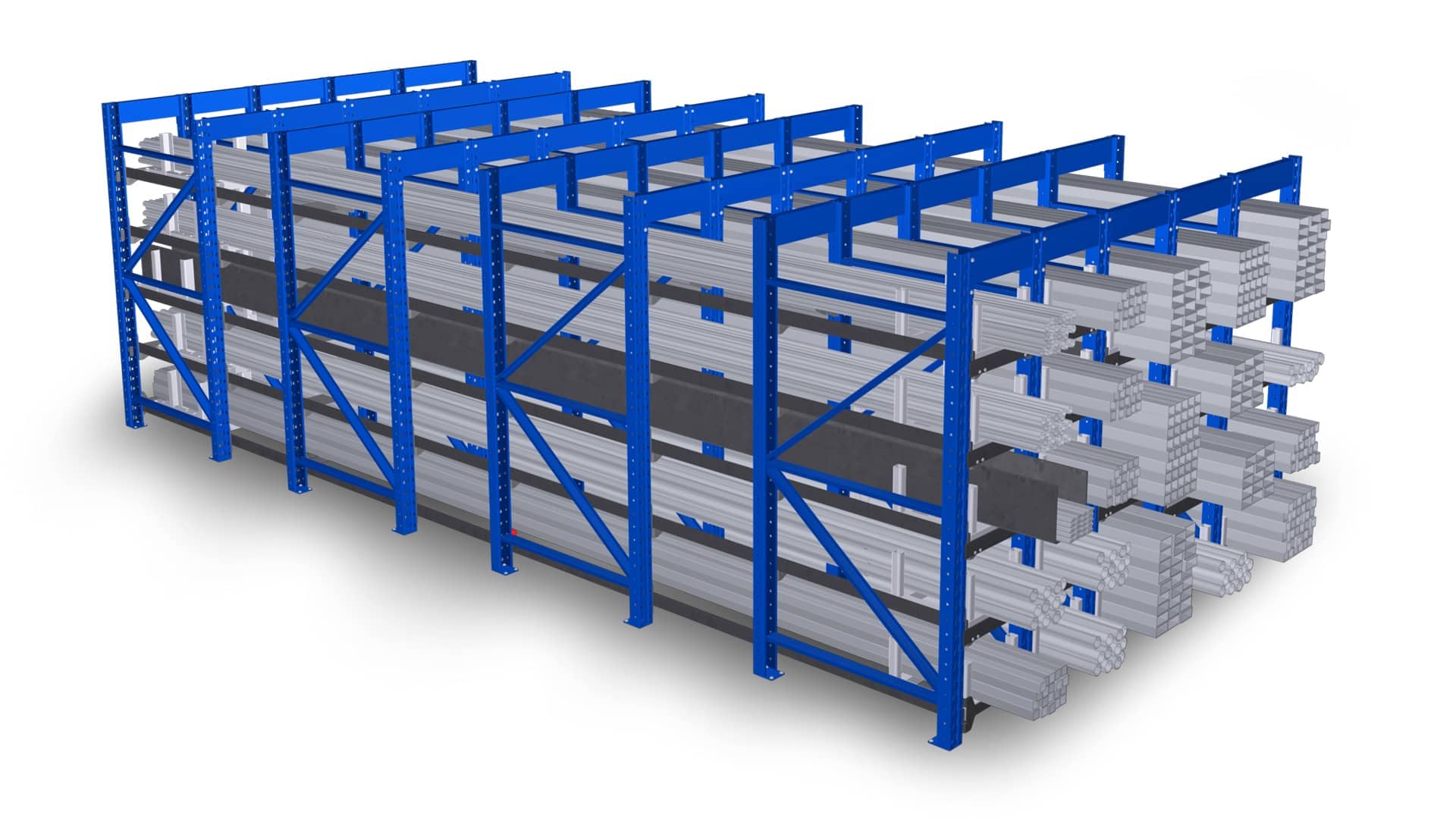

Fully customized with each application, the honeycomb rack is designed in modular construction, allowing it to be extended into unlimited adjustable slots. With a mobile trolley, it can be loaded easily and quickly. This system creates optimal use of the available space, thanks to its compact dimensions. Material can be added to any level at any time and can be developed as demand grows.

The honeycomb pan is ideal for flexible and thin material, allowing an easy transfer and secure storage in place.

Clear material arrangement and good inventory overview grants an easy and direct access to the stored materials without any waiting time. The sturdy steel construction creates a perfect base for a mezzanine. Consequently, creating extra storage space.

FEATURES OF THE HONEYCOMB RACK

- Timeless modularity

- Possibility to add a mezzanine on top

- Efficient material picking made by hand

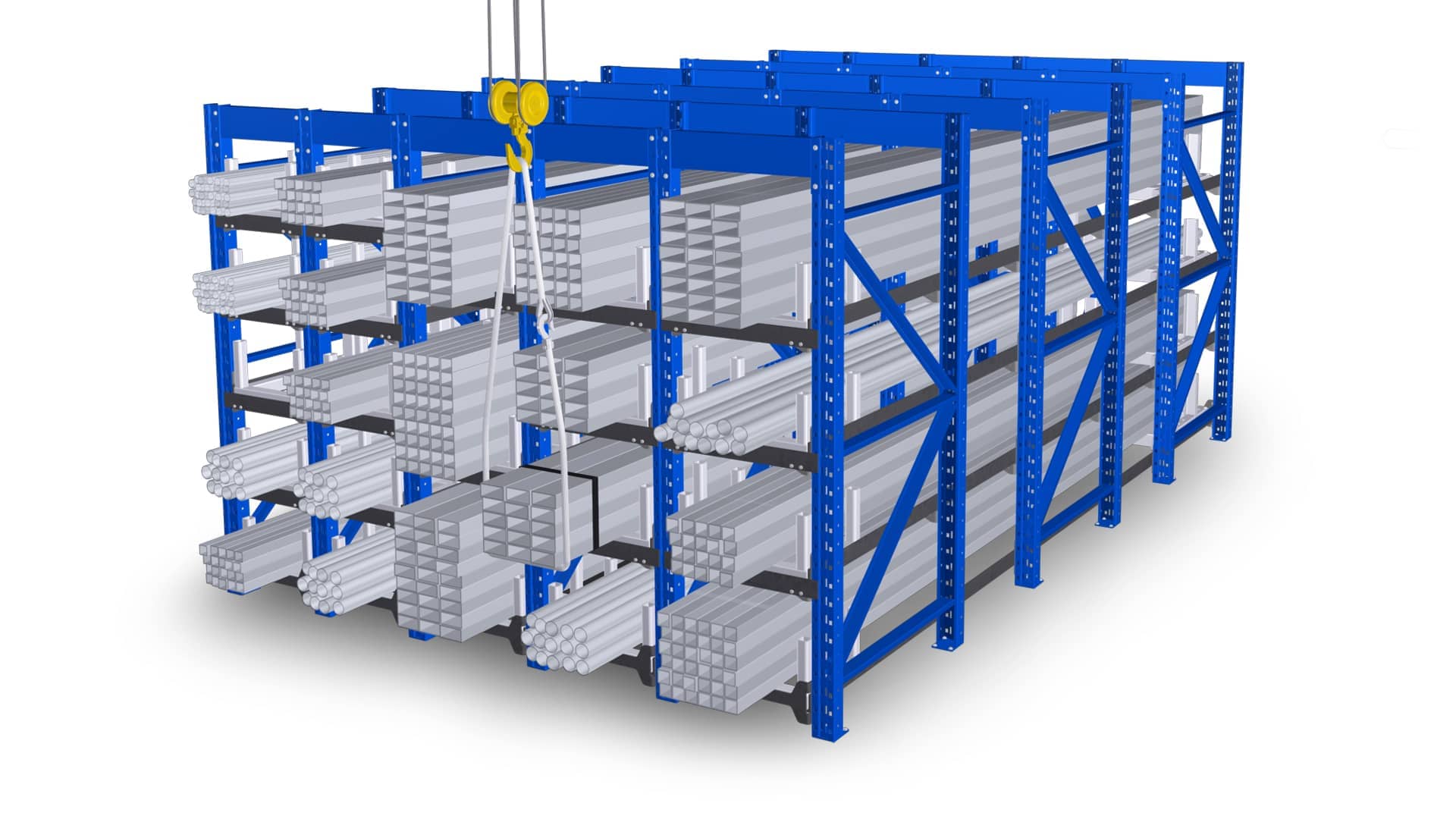

- Quick loading time of a bundle with a bridge crane

- Compact use of floor space

- Increases workers safety

SPECIFICATIONS

- Unlimited length

- 6-8-10-12’ high, customized dimensions available on request

- Capacity up to 7000-lb for each slot

- Variable slot width and height

- Closed tray available for flexible material

- Compatible with a vast type of uprights