MAKING STORAGE EASY AND SIMPLE

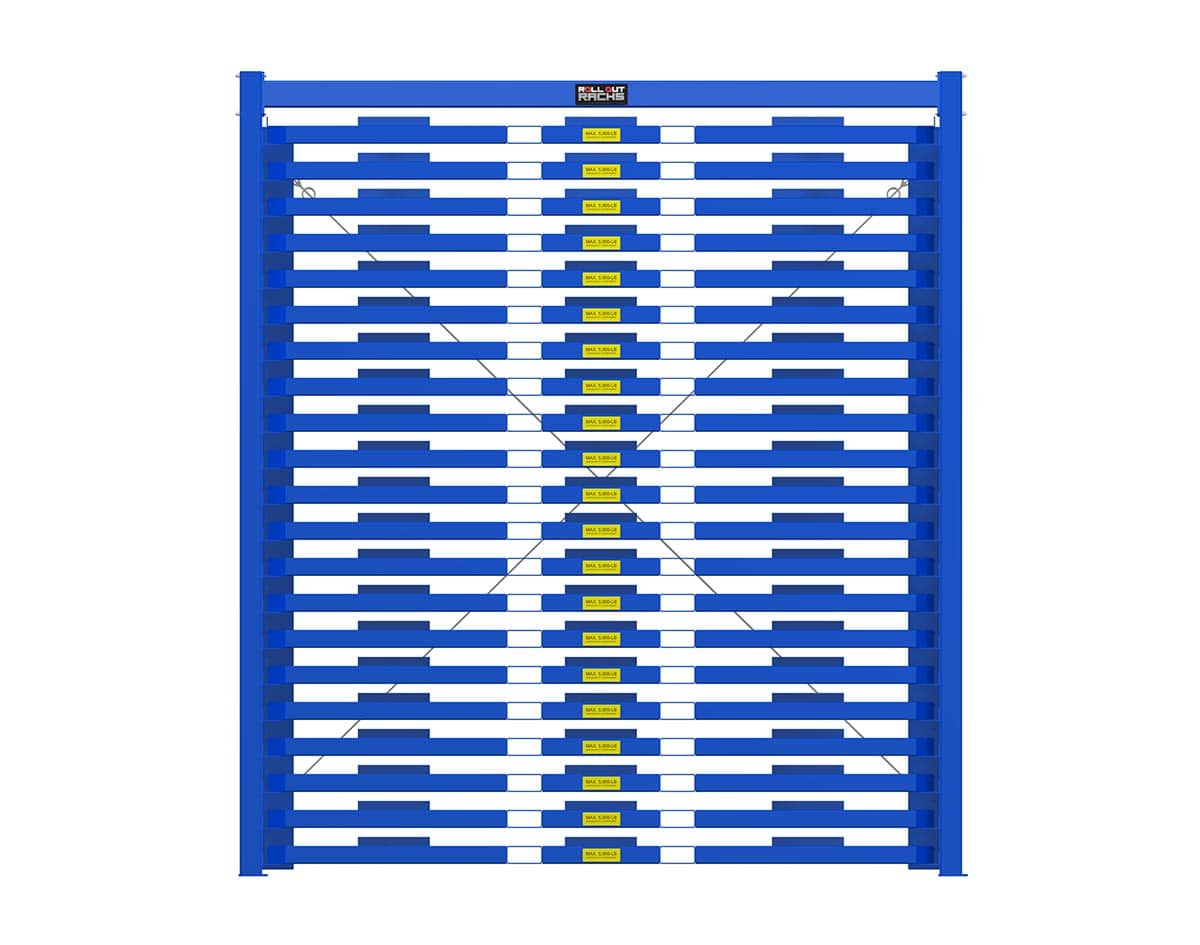

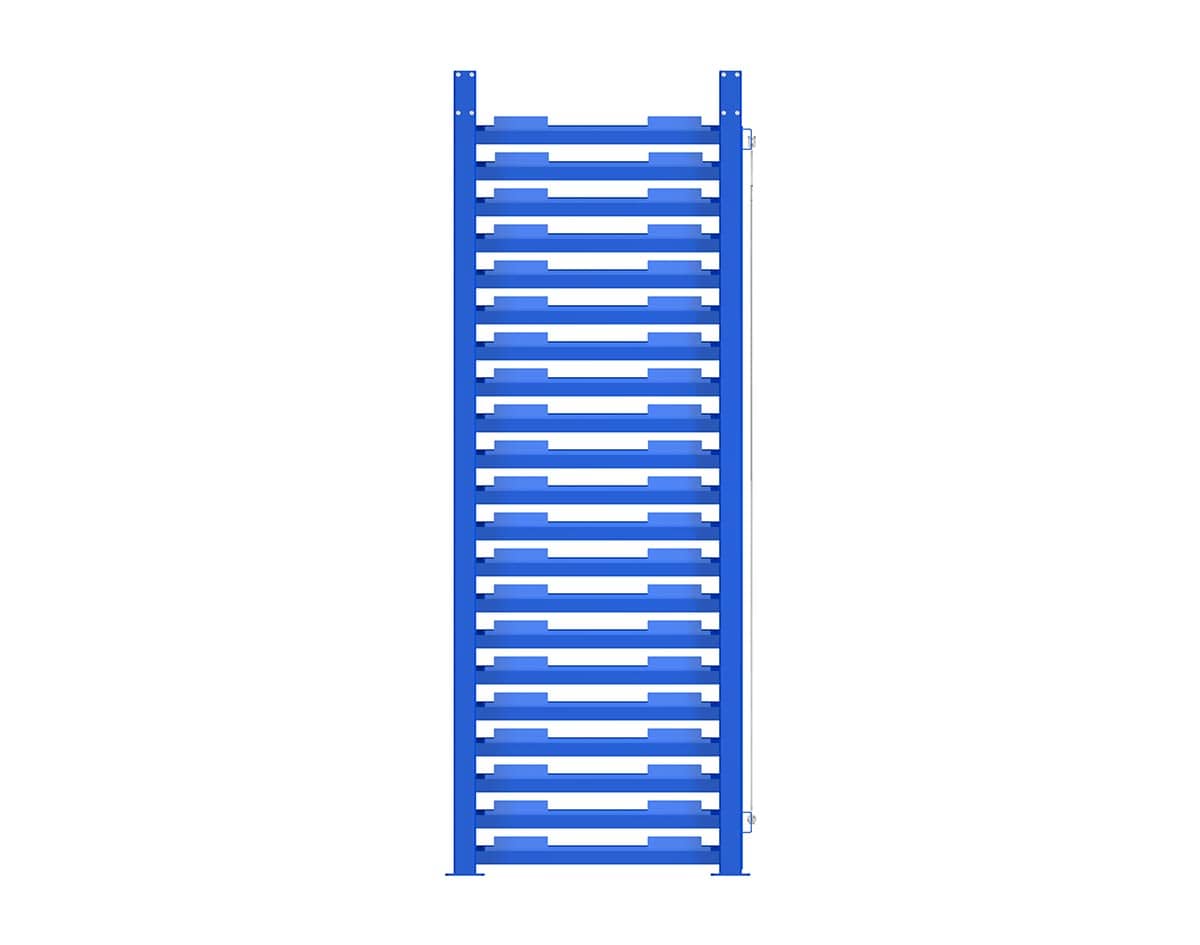

The Sheet Tower from Roll Out Racks makes easy work of handling and storing sheets of raw material. They greatly facilitate the delivery by forklift of raw sheet material to laser, plasma, and water-jet cutting machines.

Steel cartridges replace and improve upon pallets and clutter, while doubling storage space, allowing for increased productivity and safety. By freeing a considerable amount of floor space, the Sheet Tower allows personnel to move more freely and securely within the workspace. The additional floor space also allows for additional production machinery within the same layout, for increased productivity.

FEATURES OF THE ROLL OUT SHEET TOWER

- Each level of the Sheet Tower houses one cartridge with a capacity of 5,000 pounds.

- The capacity of each Sheet Tower is 200% of that of a standard pallet rack or cantilever racking.

- Sheet towers allow storage of many different types of sheet material.

- Fewer piles and easier inventory control.

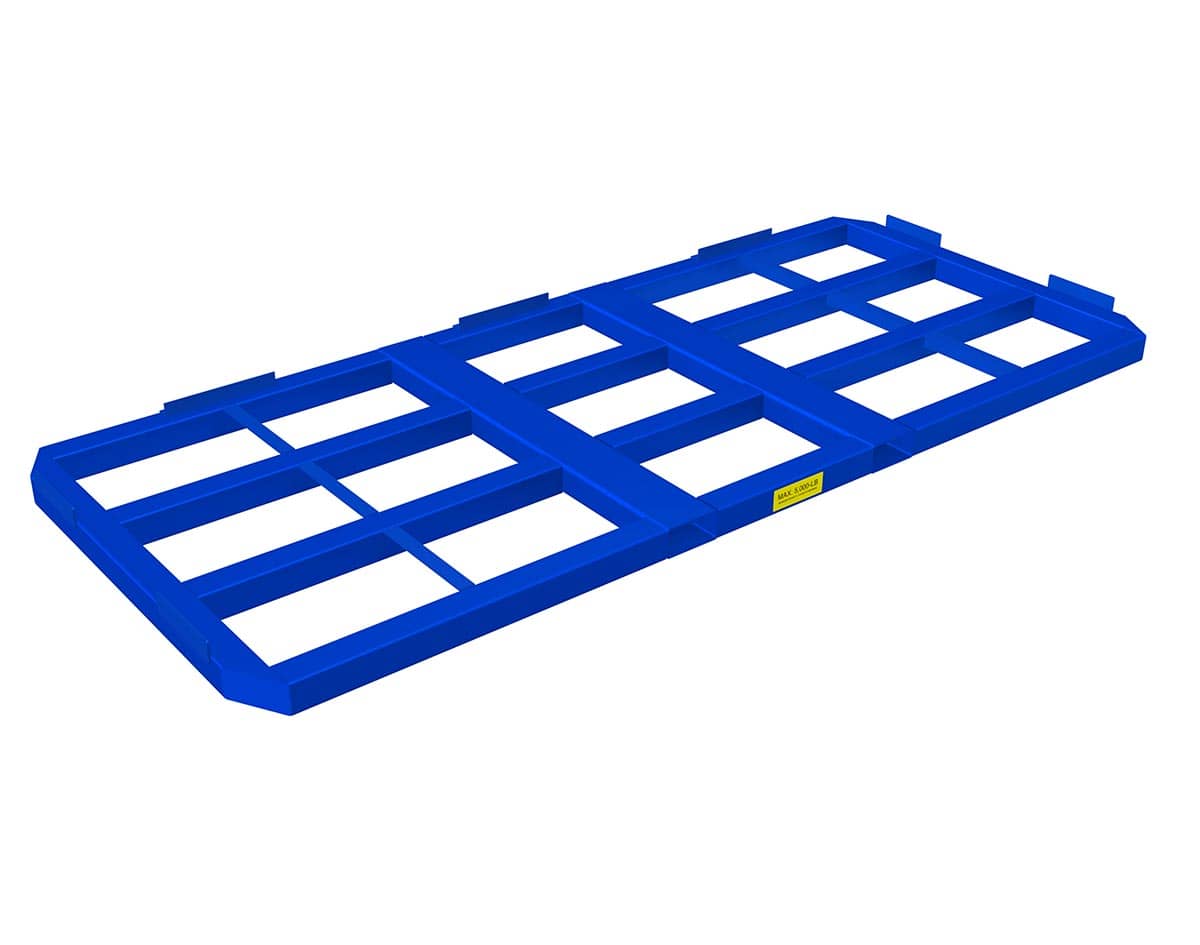

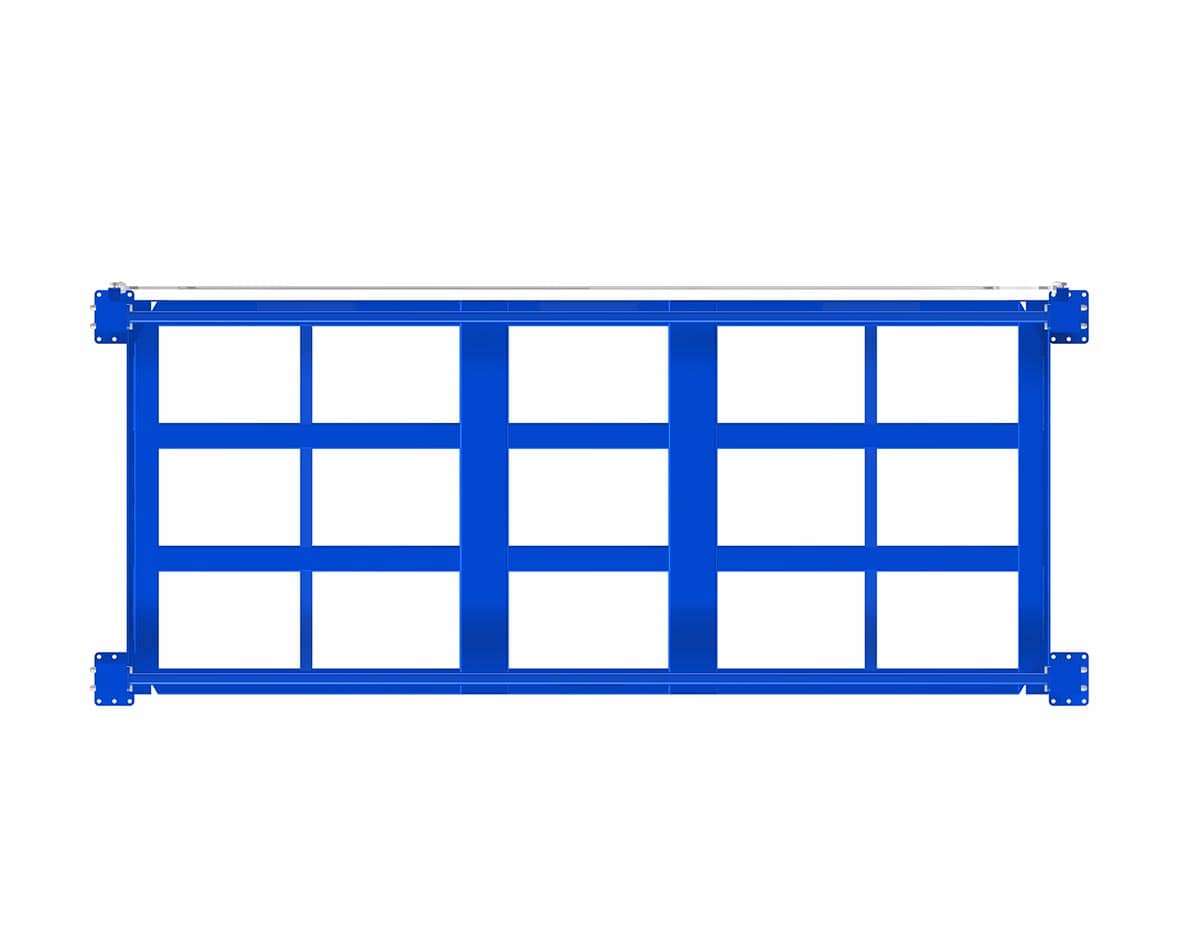

- Cartridges have lips on 3 sides to keep material from falling off when transported with a lift truck.

- Each cartridge has fork pockets built in for easy access by forklift.

SPECIFICATIONS

- Tower Heights: 8′, 10′, 12′, 14′, 16′, 18′

- Removable Cartridge Sizes: 4’ x 8’, 4’ x 10’, 5’ x 10’, 5’ x 12’, 6’ x 12

- Capacity: 5,000 lbs. per cartridge.